Estimation of the unmeasured flows from the gas wells

The Problem

Typically a sub-sea gas reservoir can consists of many developed gas fields with many clusters of gas wells. The numbers of gas wells modeled and analyzed in this project varied from 80-135 as shown below in figures.

| Reservoir Location | no of gas fields | No of well Clusters | Total no. of wells |

| West Philippines | 5 | 26 | 128 |

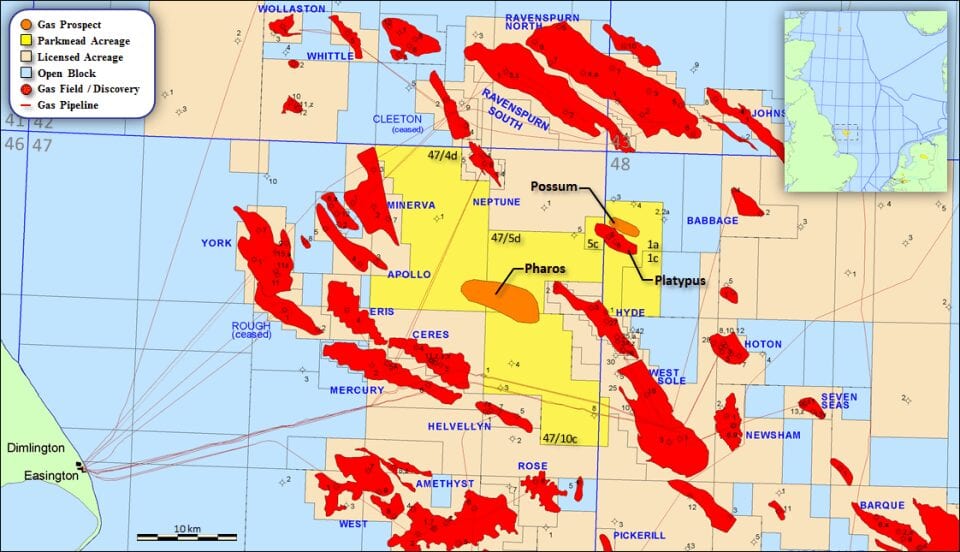

| Northern North sea | 12 | 25 | 89 |

| Southern North sea | 5 | 26 | 134 |

Each of above wells is owned by various parties and the revenue from it is nominated to its owners based on the gas produced from each well. It is also desired to optimize the gas production from each well by shutting each well in a cyclic fashion to build the producing pressure by diffusing gas from reservoir beds to the wells.

Challenges

The major challenges from the gas fields and its nominations were:

- All gas wells do not have flow meters as they are very expensive to install, installed ones may not function all the time and may not be calibrated correctly.

- To account for sub-zero sub-sea temperatures on the gas flow estimations

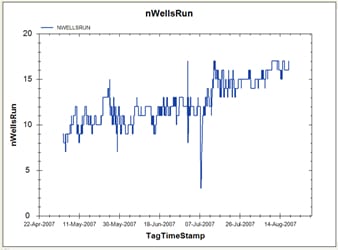

- It is desired to predict the gas well shut-in and operate cycle as the gas pressure decreases over time as gas gets depleted until the pressure builds up again. Typically, the total numbers of wells in operations can vary from 3 to 16 at any time as shown below.

Figure 2 Representative Wells operating Cycles

Project Objectives

- To design and develop a standardized data depository system using SQL server databases to hold all vast amount of field data from various projects and be able to retrieve a sub-set of this data for any analysis (currently data is stored in non-standardized Excel and MS access databases).

- To develop a generalized graphical system to visualize and analyze all well variable, analysis results to view on screen and print in PDF and printed formats

- To develop a system by which flow can be estimated from gas wells with no installed meters by using the total flow measured both at individual cluster headers and at the separator level.

- To be able to predict the total gas flow at the separator and compare it with the measured within ±5% error.

- The developed system should be able to optimize the well tuning model constants so they can be updated and used in simulation of gas production from the gas reservoir

- To be able to predict the well shut-in and operate cycles to optimize the gas productions

Our Approach

- Use ETL (Extract-Transform-Load) method to consolidate all field data to prepare for the flow estimation purpose

- Use the following models to predict the flow from the wells and reservoir. (Details of mathematical formulations of these models are outside scope of this document).

- Choke Model

- Reservoir Model

- Temperature Model

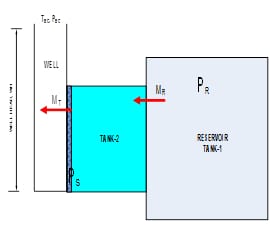

- Two tanks Model

- Composite Model (models 1,2,3)

- Global Optimizer

- Use third party non-linear regression tools

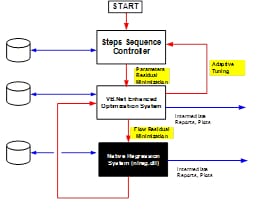

- Optimize the Model parameters and minimize the regression residual error

The End Results

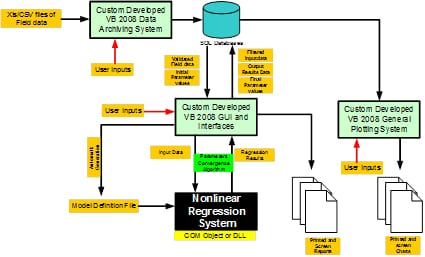

- Designed and developed gas field wells data to consolidate into SQL databases to standardize ETL process from Binary data transmitted from field to mapped data in SQL databases. The work involved database design, development of VBA/Vb.net modules, variable mapping strategy, data validation, and consistency checks etc. The size of databases involved storing of 2000+ variables and 500,000+ (one year) data records for each reservoir.

- Designed and developed a non-linear regression integrated module by using a third party com/DLL library and interfaced with SQL databases in custom developed vb.net modules. This system used all relevant models in alone and combined modes to predict the gas flow from wells as well as total flow.

Figure 3 Illustrative 2 tanks model analyzed Figure 4 Architecture to deploy non-linear regression

- Designed, developed and commissioned integrated system from data depository (ETL), performed non-linear multi-variable regression system to tune and optimize the final gas flow models parameters

Figure 5 Final Integrated Wells Flow regression System

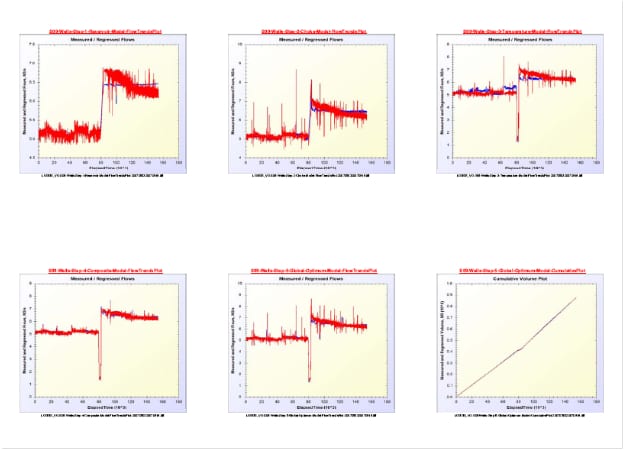

- Sample of final results

The success of regression was to be able to predict gas flows from individual gas wells (measured or unmeasured) and total gas flows at cluster nodes and top-side measurement. This was necessary for correct nomination of revenues to the wells’ individual owners.

Figure 6 Predicted vs measured flow for each well in cluster as well as total flow