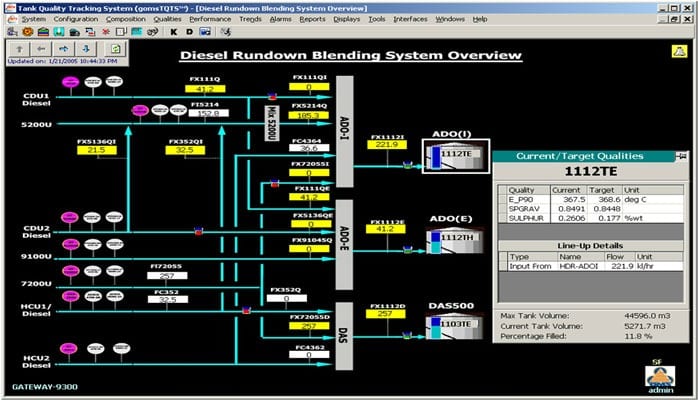

Models based predictions of tank qualities reduce lab operational cost

A typical refinery tank farm has 100-300+ tanks to store both feed stocks and final products. The analyses of 15+ qualities of each of these tanks are required by refinery operations and activities such process units control and optimization system, refinery wide planning and scheduling system, Offline and online blend optimizers, final product certifications before dispatch to the customers.

The traditional method of analyzing these tank qualities is to take infrequent samples and analyze them in the lab. This methodology is expensive, manpower intensive, time consuming and furthermore it delays the manufacturing processes due to lengthy analysis procedures. The information imparted during this webinar will discuss a model based online tanks quality tracking system how its implementation can save millions of dollars in the lab operational cost. It will also discuss the benefits of 2M$+/year realized by a refinery in Singapore by its implementation for run-down open loop diesel, Jet Fuels and Kerosene Fuels blending systems.