OMS does not offer any software of its own but offers services to custom develop and/or integrated third party systems to design, develop, commission, train users and provide end-user support for the automation of refinery offsite operations. OMS has provided the documents on our website for the education of reader and offer consulting services to implement and integrate any of the systems mentioned here in your refinery or plant.

These refinery products and systems are categorized and discussed here on this page with clickable details to follow. Each oil and gas products has the following documents:

gomsTIMS™ is an advanced, real-time Tank Inventory Management System developed by OMS to empower refineries and tank farms with precise control over their liquid assets. Seamlessly integrated with the plant’s Automatic Tank Gauging (ATG) systems, and optionally linked to blending, custody transfer, and planning modules, gomsTIMS™ delivers a powerful solution for managing inventories, minimizing losses, and streamlining operations.

This is only for testing

It is well published fact that refineries loose 40-80M$/year in lost tangible benefits. Yes, they have challenges to quantify them with real estimation methods, hence they either ignore them or are indifferent about it.

OMS has developed and tested a series of robust local Excel or web-based calculators to estimate benefits in the following areas:

1.Butane Blending

2.Crude Blending

3.Offline Blend Optimization

4.Fuel Blending Control

5.Oil movement

6.Mass Reconciliation or oil loss

OMS will release web based consolidated calculators for the estimation of all benefits

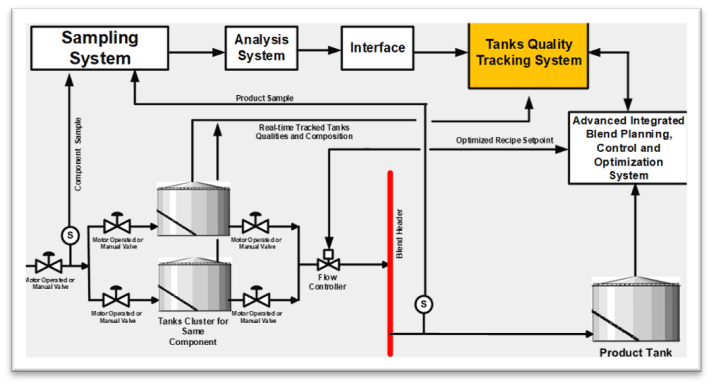

The qualities of blending component tanks are not available in real-time during planning or blending causing sub-optimal blend recipe.

OMS developed Model based tanks quality tracking system integrates tank qualities using infrequent lab analysis, upstream process unit analyzers or multiplexed analyzer at tank inlets. This facilitates blend recipe optimization using more accurate blend component qualities.

The concept has been field proven in Singapore refining with a reported savings of 2.5 Millions Dollars/year from open blending system for Diesel and Kero blend products.

The results are published in Hydrocarbon Engineering.

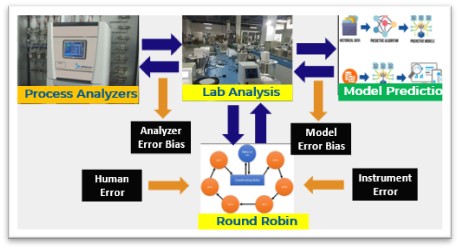

Traditional blending systems heavily rely on physical analyzers, which are prone to delays, maintenance issues, and inaccuracies in real-time blending operations.

These limitations often result in suboptimal blending, higher costs due to quality giveaways, and inefficiencies in meeting stringent quality specifications

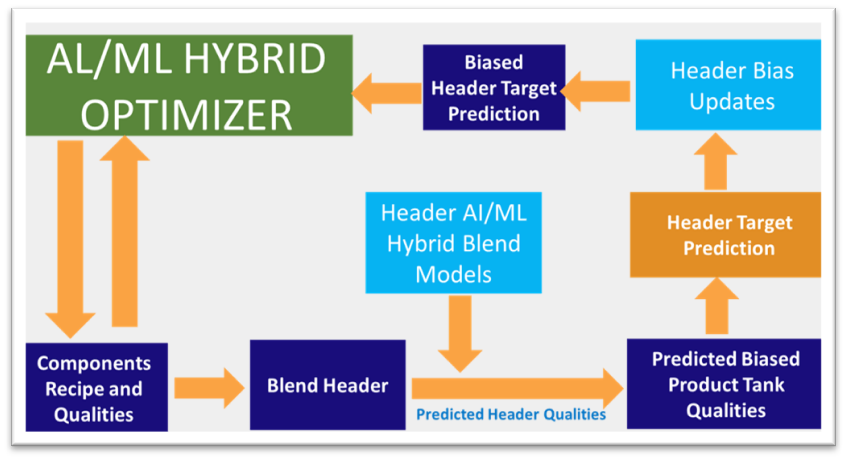

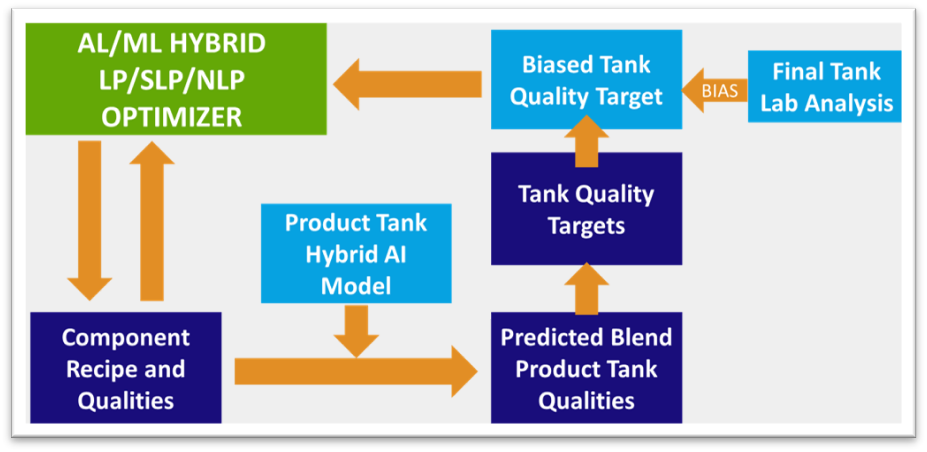

The AI/ML/FPBM-based less analyzer dependent blending system provides a revolutionary approach by leveraging advanced machine learning models and hybrid optimizers.

This patent-pending solution eliminates the need for physical analyzers, offering real-time prediction of blend qualities using historical and real-time data.

By optimizing the blend recipe and continuously predicting tank qualities, it ensures precise control, reduced quality giveaways, and improved operational efficiency.

•Predicted Header Qualities

•Biased Header Target Prediction

•Predicted Biased Product Tank Qualities

•Predicted Blend Product Tank Qualities

•Biased Tank Quality Target

•Final Tank Lab Analysis Integration

Catch wind of the latest technologies, strategies, and information to boost your business operations.