Tanks Inventory Information System

Background

It is necessary to know the plant’s present resource levels before executing the production plan. gomsTIMS™ provides the detailed information in real-time on the plants’ tanks farm inventory by interfacing with the plant’s Automatic Tanks Gauging (ATG) system and other modules in an integrated system, such as blending control, custody transfer, planning and scheduling of material movement, etc.

Applications

Tanks Inventory Management System (gomsTIMS™) can be used very effectively for:

- Custody Transfer

- Estimation of Hydrocarbon Losses

- Plant Inventory Calculations

- Liquid Assets Management

- Compliance with Local environmental regulations

- Blending of products and crude oil

Benefits

- Online real-time information of plant inventory for material movement

- Planning and scheduling of tank farm activities and maintenance

- On-line and off-line tank farm reports for management and operations

- Online Management and accounting of multi-customer products inventory

Features

- Configuration & Security

- Multi-level user access security and individual user configuration and access control

- System configuration by tank farm engineer and individual customization of user preferences by operator

- Import tank parameters from Excel worksheets for data initialization.

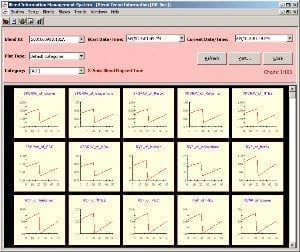

- Online Trends

- Any tank gauging parameters or tank inventory can be viewed online historically

- User can define his own groups of trends for easy retrieval and viewing

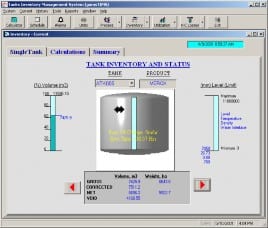

- Inventory Calculations

- Online Calculations for Temperature compensation by ASTM tables at 15 or 20 degree C

- Perform quick calculations of tank inventory and level for loading and unloading operations with an online calculator

- Historical Data

- Configure interval logging reports for product movement tracking

- Monitor tank gauges data and inventory online in graphical and tabular formats

- Historical data available online for tank gauging and product inventory

- Liquid Asset Management

- Online current and historical calculation of tank capacity utilization for management review for optimum usage of tank farm

- Hydrocarbon Losses

- Online current and historical calculations of both standing and movement fugitive tank losses to comply with local environment regulations

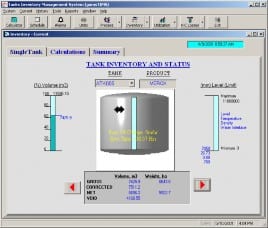

Figure – 1 Online Inventory and gauging display

-

-

- Unlimited Strapping points and initialization of mathematical calculations by tank geometries. Plant engineer can modify these data to reflect actual tank deformation.

- Export of tank data to Excel worksheet format

- Customize input and output units of tank gauging and inventory data

- Real-time Monitoring

- Real-time tank gauging and tank inventory information for tank-wise and product-wise

- Graphical information of tank gauging and tank inventory parameters

-

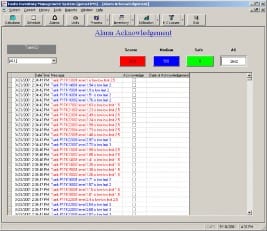

Alarms Management

-

- Real-time status, management and logging of tank alarms

Figure – 2 Management of Tank Alarms

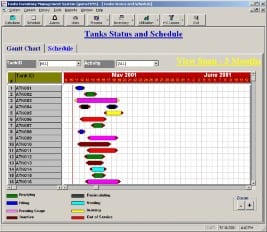

Figure – 4 Tank Farm Activities Scheduling

- Scheduling

- Scheduled, planned and actual tank activities can be viewed in both tabular and graphical formats

Economics

Economically, it is estimated an annual savings of $1 M – 3.5MUS$ by inventory reduction, automatic line-up, minimization of spills, savings in custody transfer and real-time inventory information by implementation of gomsTIMS™.

System Requirements

Pentium III or higher, 650+ MHZ, 256 MB RAM, 20 GB+ HDD, CD ROM, 17”+ color monitor, Window NT/2000 OS

Contact Information

Offsite Management Systems LLC

2003 Baker Estates Dr. Houston, Texas 77094, USA

Tel: +1-832-821-8001 Fax: 866-450-4035

Email: info@globaloms.com Web: www.globaloms.com

Copyright 2000-2015 Offsite Management Systems LLC. All rights

reserved. OMS™, OMS logo (Tri-circle Triangle), ”…Redefining

Excellence, gomsTQTS™ are trademarks of Offsite Management

Systems LLC, USA.