Regulatory Blend Control

Background

In a three-tier architecture of the blending control system, the refinery planner prepares a blend recipe by using gomsPOFBlend™ offline blend optimizer and downloads the blend order to the offsite operations department to execute it online. The objective of blending operations then becomes to make the blend within planner’s specified constraints yet with latest and sometimes dynamic process conditions. This necessitates the implementation of online blend control and optimization system (gomsPONBlend™) to produce blend with minimum quality giveaway, safely and efficiently

Applications

Online blending control and optimization scheduling system (gomsPONBlend™) can be used very effectively for:

- Online Execution of planner’s recipe for Gasoline, Diesel and Fuel oil products in a tanks-to-tank blending configuration

- Control the feed quality of the crude unit by blending crude from various sources varying in quality

- Online quality control of run-downs from process units in continuous blending configuration

Benefits

- Minimizes or eliminates the effect of dynamically changing process conditions such as component qualities

- Blends in most economical way by minimizing quality giveaways within planner’s specified constraints

- Online certification for direct blending into pipeline or ship

- Production of economically optimum product blends, thereby adding to refinery’s bottom line profitability

- Eliminates reblends due to violated specs and lack of in-line control

- Flexible configuration of sources and destinations of blends covers all refinery setups.

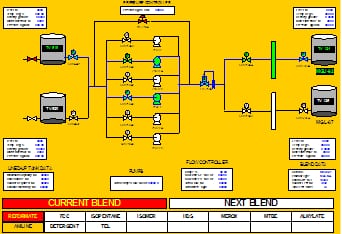

Figure 1 Blend line-up display

Figure 1 Blend line-up display

Features

- Blend Setup

- Interfaces with gomsRCPBlend™ or any third party Regulatory Blend control and offline optimizer

- Auto setup of multiple blenders headers dynamically for product swings

- Initializes the optimizer to check initial data integrity and online control feasibility

- Blend Monitoring

- Automatically collects 250+ pre-configured blend variables for every cycle of execution of tank quality tracking run.

- Monitors online header and stocks analyzers and integrates the latest results in the optimum recipe.

- Group trends of all monitored blend variables.

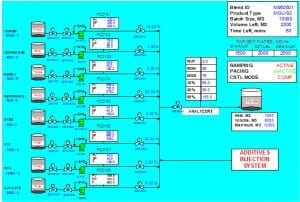

- Additive dosage control and monitoring

Figure 2 Regulatory Blend Control Monitoring Display

Figure 2 Regulatory Blend Control Monitoring Display

Recipe Control & Optimization

gomsPONBlend™ controls the recipe of blend and optimizes every 10 minutes by analyzing the stock qualities and current and target qualities of final product tanks. It archives the LP matrix and solution of every optimizer execution which can be exported to gomsBlendOpt™ system for later analysis and diagnosis.

Interfaces

- Regulatory Control Product Blend System gomsRCPBlend™ or any other third party system

- Offline blend planning, scheduling and optimization system (gomsPOFBlend™)

- Tank gauging system and tanks farm inventory management system gomsTIMS™

- gomsTQTS™ for online tank quality tracking system.

- Blend Information Management System for feedback of model biases (gomsBIMS™)

Economics

Economically, it is estimated an annual savings of 5–7MUS$ by online Blend Control and optimization alone. These benefits are achieved cumulatively by integrated three-tier implementation of offline, online and regulator blend control systems.

System Requirements

Pentium III or higher, 650+ MHZ, 256 MB RAM, 20 GB+ HDD, CD ROM, 17”+ color monitor, Window NT/2000 OS

Contact Information

Offsite Management Systems LLC

2003 Baker Estates Dr. Houston, Texas 77094, USA

Tel: +1-832-821-8001 Fax: 866-450-4035

Email: info@globaloms.com Web: www.globaloms.com

Copyright 2000-2015 Offsite Management Systems LLC. All rights reserved. OMS™, OMS logo (Tri-circle Triangle), ”…Redefining Excellence”, gomsTIMS™, gomsTQTS™, gomsPONBlend™, gomsPOFBlend™, gomsBIMS are trademarks of Offsite Management Systems LLC, USA.