Evaluation Study of a Refinery Mass Reconciliation Software

The Problem

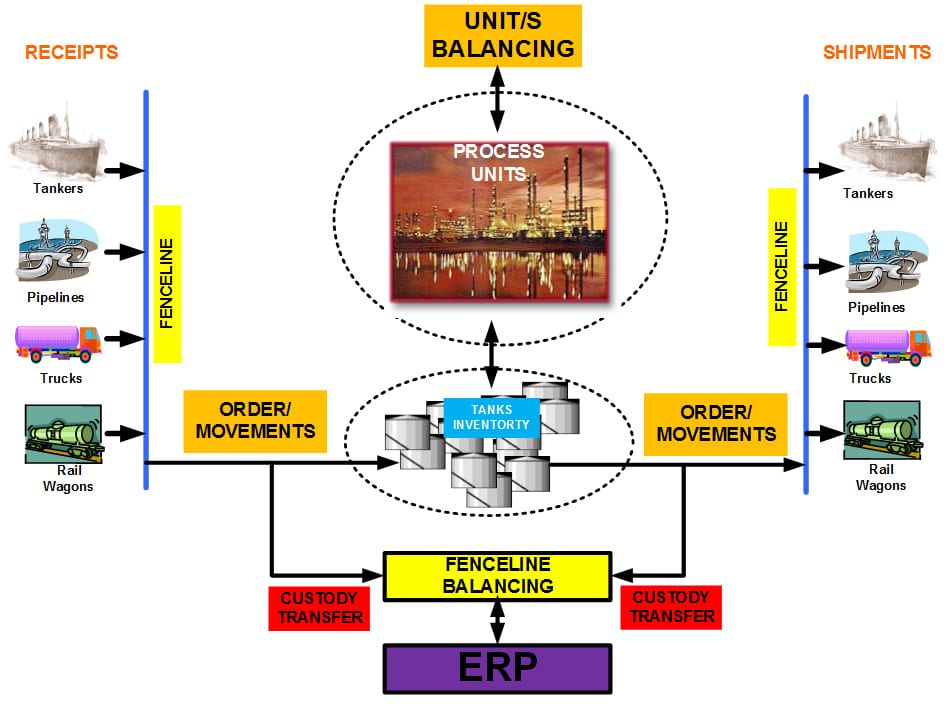

Shell oil had initiated software projects to implement assets management systems (Tanks Information System and oil movement management ) from automation vendor Invensys and ERP system (OAS) to integrate into a complete Hydrocarbon Management System (HM). However, the corporation felt that there should be another cross-check for fence-line balancing in this integrated system as fence-line balancing was affecting the bottom-line due to mismatches in orders and executions. MAB (Mass Accounting Balance) from the same vendor Invensys was chosen to evaluate its suitability to fit the requirement of fence-line balancing as an integral part of the Hydrocarbon Management (HM) in 10 of Shell US and Non-US refineries.

Challenges

MAB (Material Balance) is a module from Invensys for the mass reconciliation purpose. It is seamlessly integrated with OMM-TIS using the same off-site database. However, the software MAB from the vendor was primarily developed for the truck terminals and was not deployed by Invensys for general mass reconciliation in a refinery. The foremost challenge was to evaluate the software and enlist enhancements that are needed by the vendor to make it suitable to use as integrated tool for the general mass reconciliation and not just fence-line balancing.

Project Objectives

The project objectives were divided into the following categories:

- Evaluate and enlist the deficiencies MAB from Invensys to fit as general Refinery Mass Balancing tool to integrate with Invensys’ OMM and TIS modules

- Use two of shell refineries, US and Non-US based, to demonstrate proof-of-concepts to use MAB integrated with OMM/TIS at these refineries

- Make a business case of implementing MAB for 10 of Shell refineries where OMM/TIS were already implemented

Our Approach

We used Stage Gates (SG1 and SG2) shell’s Project Delivery Framework (PDF) for the MAB study to approach the project as follows:

- Install Invensys’ OMM/TIS and MAB in Virtual Machine (VMware) environment to install live system from two of Shell’s US and Non-US refineries to evaluate MAB integrated with OMM/TIS

- Test and evaluate all functionalities of MAB with actual reconciliation in MAB and compare it with refineries’ reconciliations using another vendor ASPEN’s reconciliation software namely Advisor

- Identified and enlisted enhancements required in MAB by the vendor

- Analyzed refineries’ monthly reconciliation data and determined they were either erroneous or out of industry average oil loss

- Made a business case to implement enhanced MAB in 10 of the Shell Refineries

The End Result

The MAB evaluation study concluded the followings:

- Current HM landscape uses Advisor to do mass reconciliation and cross-check fence-line movements with SHARE/SAP in the form of a comparative SAP report (Advisor versus SAP values).

- This functionality will not be available long term, thus leaving a business gap for doing daily/monthly mass reconciliation and generating a comparative report.

- Evaluation of historical monthly mass reconciliation data for two refineries showed that

- % loss/gain were not within industry average

- Variation in monthly % loss/gain was not normal

- % loss/gain in mass was positive for many months and it is not normal as there can never a positive gain in mass and negative gain in volume. This affects the financial results.

- Accurate and more timely (daily or weekly versus monthly) reconciliation would minimize above discrepancies and increase quality and accuracy of mass /volume reconciliation

- MAB would facilitate a single point for reconciliation activities showing all possible imbalanced movements as compared to current practice of reconciling individual movements in OMM-TIS without a view of over-all balance.

- Possible tangible benefits will be due to

- Improved % loss/gain – estimated benefits 1M$-8M$/year/refinery

- Improved efficiency in mass reconciliation efforts

- Improved quality and accuracy of %loss/gain and financial results

Other Related Information

If you would like to learn more on Hydrocarbon Management (HM) in a refinery, please click here for OMS webinar.