It is becoming difficult for refining industry worldwide to cope with strict fuel quality and emission control requirements and regulations by local and foreign consumers and authorities. Unstable and high crude oil prices add further to their pain. Refiners are resorting to methods to conform to low sulfur, low toxic content fuel specifications and finding that advanced control, and optimization system, in addition to process unit modification and additions, is a suitable, workable and economical solution.

However, successful implementation of an advanced control and optimization system for gasoline, diesel and fuel oil products requires that both plant operators and engineers alike understand in details the technology and operations of such system available in the market place today. This workshop will cover in details each aspect of hardware, field equipment, software, interfaces and over-all integration of an advanced blend control system to leave the attendees with deep understanding and working knowledge of such a system.

PROGRAM OUTLINE

Each of modules below will discuss 4-5 topics each of 20-30 minutes duration. The entire course will be covered in 880+ slides.

Module-1 Overview and Fundamentals

- Overview of Refining

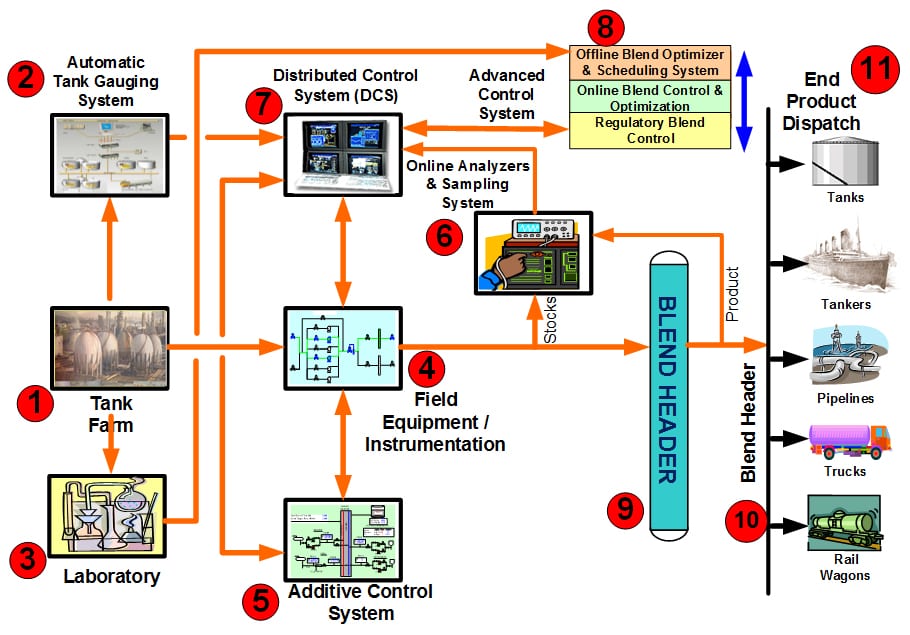

- Refinery Offsite Operations

- Fuel Blending Operations in Refining

- Blending Problems and Challenges

- Road-map to Efficient and Effective Refinery Offsite Operations

Module-2 Blending Field Equipment

- Blenders Configurations

- Tank Farm and Automatic Tank Gauging System

- Pumps, MOV’s and Control Valves

- Additives Control and Monitoring

- Blend Header Design Considerations

Module-3 Qualities Analysis and Measurements

- Quality Relationships and Measurements

- Lab Analysis of Stock and Product Qualities

- Online Analysis of Stock and Header Qualities

- Model Based Tank Qualities Measurement

Module-4 All About Octane and its Measurement

- The Mysteries of Octane

- The Journey of Octane thru Refinery Lanes

- Octane Measurement by Knock Engine

- Integrated Analyzers Technology and Applications

- Octane Measurement by Spectrum based technology

- Comparison of Knock engine versus Spectrum based methods

- NIR and NMR versus CFR analyzers – Selection and Cost Effectiveness

Module-5 Linear and Non-linear Blend Models

- Linear Blend Models

- Non-linear Blend Models

- Methods to Handle Blend Non-linearity

- Control Matrix of Qualities

- Gasoline, Diesel and Fuel Oils Specifications

Module-6 Blend Optimization and Specifications

- Advanced Blend Control Strategy

- Blend Optimization

- How to estimate and update Blending values

- Gasoline, Diesel and Fuel Oils Specifications

- Biofuels – A perspective Part-I

- Gasohol Biofuels – A perspective Part-II Biodiesel

Module-7 Regulatory Blend Control

- Optimum Blend Control System Strategy

- Regulatory Blend Control Operations

- Blend Trim Control

- Ethanol Blending

Module-8 Off-line Blend Optimization and Planning

- Refinery-wide Planning & Scheduling

- Offline Blend Planning and Optimization

- Demonstration of An Offline Blend Optimizer System

- Lab Exercise to solve an LP problem of a small refinery

Module-9 Online Blend Optimization and Planning

- Advanced Online Blend Control & Optimization

- Control and Optimization of run-down blending system

- Data Reconciliation and Feedback

- Technology Set of Hardware and software

- System Architecture – Integration and Interfaces y

Module-10 Blending Project Justification

- Where and how to start

- Methodology to Assess the Current State of Blending

- Identifications of Automation Areas

- The Quality giveaway – Concept, Cost and reduction Benefits

- Data gathering and Analysis

Module-11 Blending Project Implementation

- How to implement a oil movement and control project

- How to implement a blending control and optimization project

- How to realize and sustain benefits

- Required Enterprise Changes

Module-12 Collaboration and Reconciliation of Process and Data

- The Hydrocarbon Management (HM) in the Refining Industry

- Collaboration of Data and Process for Refinery Offsite Operations

- A treatise of ASTM Standards

Who Should Attend?

- Mandatory – OM&S Manager, Blending Manager, Process Engineer, Blending Engineer, Control System Engineer, Analyzer Engineer, Offsite Operator, Blending Operator, Fuels Traders, Crude Traders

- Recommended – Control System Manager, IT Manager, Refinery Planner, Refinery Scheduler, Blending scheduler.

- Optional – Refinery Manager, IT/Engineers/Analyst, Field Operator, Maintenance Engineer

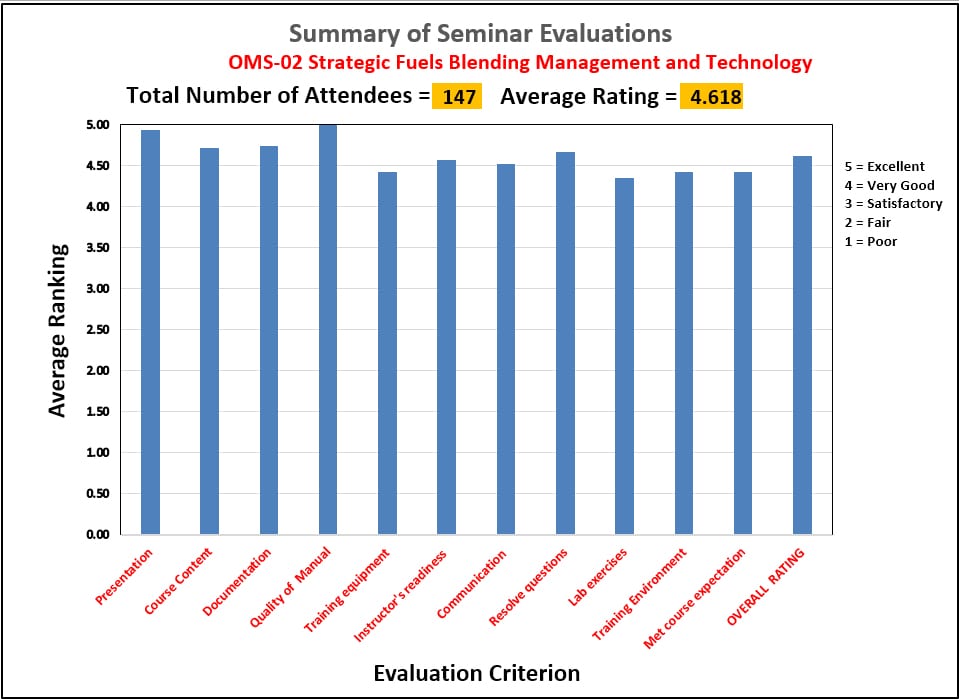

Summary of Course Evaluation

Each course is evaluated by the course attendees for the following 12 categories, as in the figure shown below.

Few Testimonials

I have not attended any training course before which is so organized, exceptional, rich in topics and presented excellently.

Thanks to the instructor, I learned much about fuel blending in this course. — Sergio Carvajal – IST corporation

The octane quiz was exciting as it cleared many misconceptions about octane. I would give 5 stars to this

course and the instructor, Dr. Agrawal — William Bautista, IST Corporation

The concept of Blender header design was very innovative as it was developed and taught by the instructor. It took the

notion out that the blend header is just a piece of pipe. Thanks to Dr. Agrawal, it has many design considerations important to the success of

the blending system. He deserved a standing ovation. —- Mike Redd, Silver Eagle Refining

The course was exciting as I could relate to the refining and auto industry problems and challenges regarding fuel quality specifications and ways to meet them economically. — Jay Cummings, GM

I wish you would offer this excellent course in India as we have 15 refineries that all focus on onsite

and ignore offsite operations, which you showed to affect the refinery’s bottom line. – Kothapalli Srinivas, Numaligarh Refinery, India

The instructor is highly knowledgeable and very interactive with the class participants. — Alan Hugo, Valero

I liked that the course started with general concepts and continued to detail, giving space to change the amount

of details/time dedicated to topics relating to the audience. The material of the course was excellent. This seminar

provides the refiners with an in-depth look at blending and how to save the company money. —Mohammad Al-Buftain, KPC

The discussion of case studies of the refinery’s progress to migrate from manual blending control to a fully automated

system was exciting as it showed the problems, challenges, and solutions at every step of the upgrade.

Excellent course material and the expertise of the instructor – Singapore Refining Company

The discussion of our refinery fuels blending problem at the end was constructive and gave us directions

to move towards. Thank you very much, Dr. Agrawal – BP Oil, India

Past Participants